Die & Cores

Optimized & Industry-ready Blow Bottle Solutions

For All Your Complicated Needs

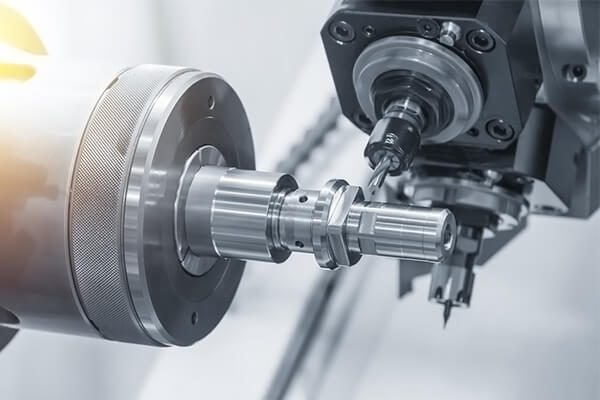

Casting, forming and pressing can be among the most efficient methods of manufacturing with speed and repeatability. However, the production of the ancillary manufacturing equipment required to work this way can be even more complex than the product itself. For the final part to meet specification, the tooling must also be produced to the correct tolerances. The challenge for toolmakers is to ensure that every mould, die and machine tool, as well as their jigs, fixtures and gauges, are fit for purpose and ensure quality output every time.

Our Innovations

Focus On Your Blow Moulds

Die & Cores

Die & core is the install on the die head,it is channel of parison from die head.It control the size and shape of parison.Finally it will control the wall thickness of product after blowing.

Die & Cores

Round product suitable to use round shape die & core.But some products are other shapes,square,flat or special shape. We have rich experience to design and adjust ovality to let the wall thickness everage to prevent product out of shape.