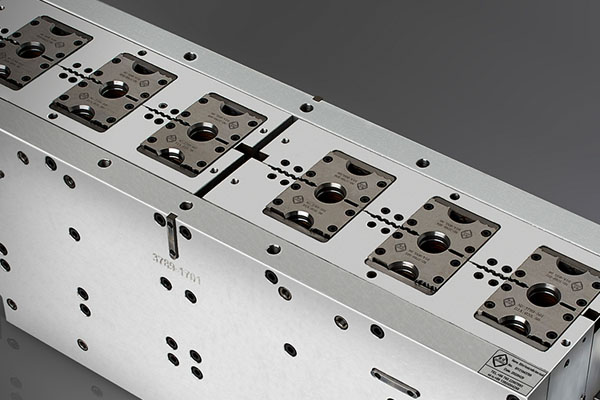

Blow Pins

Optimized & Industry-ready Blow Bottle Solutions

For All Your Complicated Needs

BOYU supplies blow moulds for the beverage, food, and consumer goods industry to fit most of the major brands of re-heat stretch blow moulder machines. Our blowing specialists can advise you on how to achieve the best possible bottle quality even before the start of the production.

In our laboratories, extensive tests and inspections are performed on both molds and sample bottles through high-quality measuring and testing equipment.

BOYU produces aluminum and stainless steel moulds for any application and any shape of container.

Our Innovations

Focus On Your Blow Moulds

Blow Pins

A plastic bottle is formed by extruding a hot plastic parison around a blow pin within a two-part mold.The blow pin is cooled by the air pressure and has an elongated lower tubular portion with air holes which are slanted upwardly to form a selected blow air pattern to aid in forming the handle portion of the bottle.The structure of blow pin include blow pin,blow tip and cutting sleeve.The material of our blow pin is S136H,we use S136H or BeCu for blow tip and the cutting sleeve is SKD11.

Blow Pins

The structure of blow pin include blow pin,blow tip and cutting sleeve.The material of our blow pin is S136H,we use S136H or BeCu for blow tip and the cutting sleeve is SKD11.We provide OEM service of blow pin as per client’s same base on the machine.